Frequently Asked Questions

At WQ-iC, our commitment to quality, integrity, and impartiality is demonstrated by our UKAS accreditation and being appointed by DBT as an Approved Organisation.

For guaranteed quality and accuracy, all welding certification is issued and approved under the control of a certified European and International Welding Engineer.

The definition in the BS EN ISO series of standards (see ISO 15607) is written in a very neutral context. This is because the series of standards could support a wide range of industrial sectors.

In some contract specifications, application standards and / or directives it can be specified that the use of an independent examining body is required to verify compliance for all the witnessing, testing & certification of WPQR’s and Welder Qualifications. To satisfy these requirements it usually means that the fabrication company will need to engage an Independent ISO / IEC 17020 Inspection Body, this proves integrity and a fully traceable system is applied throughout the whole verification process.

When a fabrication company is looking to comply with a contract, make sure that the welding qualifications that are going to be applied to the project not only cover the applicable qualification ranges, but also that the person / organisation that issued the qualifications is going to be acceptable to all contracting parties.

This would depend on what industry sector you are working in and also if an application standard was specified. For example, BS 4872 may be applicable to satisfy general ISO 9001 quality requirements. If the welder was required to work on pipework or pressure vessels or structural steelwork then BS EN 287-1 or BS EN ISO 9606 welder qualification may be required.

A welding procedure test is required to demonstrate that the organisation performing the welding can select appropriate welding conditions, that could include such variables as preheat, correct consumables and welding parameters etc. to meet the applicable standard.

The welding procedure test demonstrates technical control from the manufacturer performing welding and also proves mechanical and metallurgical properties. In some situations special tests such as corrosion testing may also be required.

The welder qualification test is all about the skill of the welder to produce an acceptable weld.

The position is known as H-L045. Pipe axis 45 degrees inclined from the horizontal and the welder welds in a vertical up direction without rotating the pipe. The welder needs to be competent to produce a test in this position.

Typically, a BS EN ISO 9606-1 welder qualification is valid for two or three years depending on your requirements and preferences, provided the welder remains active in the process and position certified. We also require 6-month continuity records, signed by an approved supervisor, to keep it valid. If the welder hasn’t used the process for over 6 months, a retest may be needed.

WQ Inspection & Certification Ltd (WQiC) offers unmatched expertise with over 10 years in the industry and is led by an International Welding Engineer with over 20 years’ experience and experienced qualified staff proficient in this industry. They provide UKAS accredited, high-quality welding certifications that meet global standards. With UKAS accreditations to ISO/IEC 17020 for Inspection, ISO/IEC 17024 for Personnel Certification, ISO/IEC 17025 for Testing, our own NDT company and personalized service, they ensure your certifications are fast, accurate, reliable, and tailored to your specific needs. WQiC stays up to date with the latest industry codes and standards and are well placed on international welding committees such as WEE/36, so you can trust your certification is current and compliant. |

At WQ Inspection & Certification Ltd, we provide a full range of welder qualifications to BS EN ISO 9606-1 for steel and BS EN ISO 9606-2 for aluminium, among others. We also certify welding procedures to ISO 15614, ASME Section IX, AWS D1.1 and more specialist standards depending on your project or industry requirements. Whether it’s TIG, MAG, MMA or FCAW, we’ve got you covered.

A Welder Qualification Test (WQT) proves the welder can produce welds of sound quality according to a given procedure. The Welding Procedure Qualification Record (WPQR), on the other hand, is a documented procedure that demonstrates the process is fit for the intended service. In short: WQT qualifies the person, WPQR qualifies the method.

We aim to issue your certificate within 7–10 working days for WPQR and even quicker for WQT’s. If it’s urgent, let us know. We offer a fast-track service in special cases.

We certify to a broad range of international and British standards, including:

- BS EN ISO 9606 series – Welder qualification

- ISO 15614 series – Welding procedure qualification

- ASME Section IX – For pressure-related work

We can also assist with UKCA, EUCE certification (through our partner LRQA) and information regarding structural steel compliance to EN 1090.

Yes—if you’re working on pressure systems, structural steel, or anything falling under regulated codes (PED, EN 1090, etc.), certification is a legal and contractual requirement. Even outside regulated work, having certified welders improves traceability and quality assurance.

No, we primarily offer testing and certification, but we work closely with accredited training centres. We’re happy to recommend a reputable provider if your welders need assistance prior to testing.

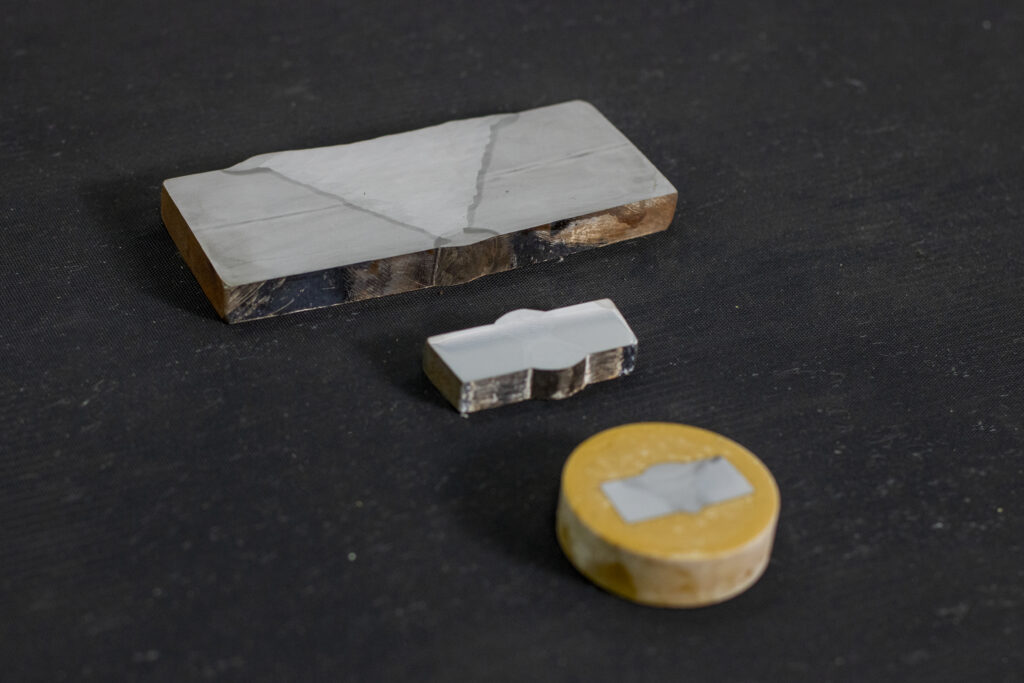

This will depend on the qualification standard, weld process and joint type. For example, a butt weld in plate could be tested by radiography or bend testing and a fillet weld could be tested by macro and/or fracture testing. All of this will take place once the test piece has been witnessed, verified and passed visual examination with one of our approved welding examiners.

If it’s to BS EN ISO 9606-1, your plates need to be 200mm x 125mm and your pipes need to be 125mm long. For a WPQR to BS EN ISO 15614-1, plates need to be a minimum of 350mm x 150mm long and your pipes will depend on your outside diameter and if you have any additional testing requirements that would require extra material. If in doubt or for any other standard, always feel free to give our friendly, knowledgeable team a call prior to test.

Yes, we have 2 bespoke weld bays and a small stock of material and consumables ready for welders to use. Just book in with our team to ensure they’re available for use.